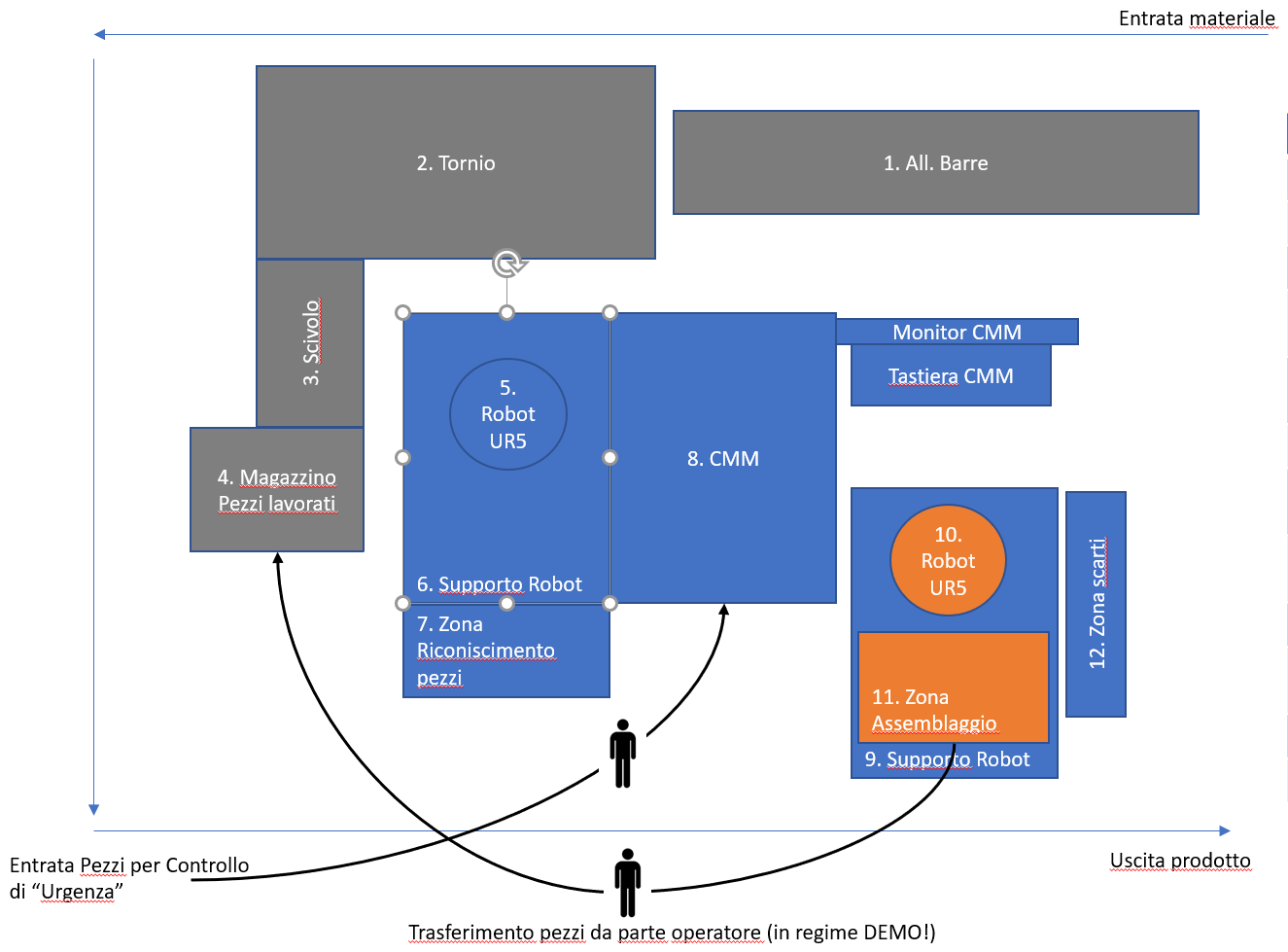

Upon entering MECSPE Bari, visitors will be welcomed by a Smart Factory, where machinery and humans collaborate in the production process, with the exchange of useful information, in both directions

A multi-level “intelligence” which provides prompt information on any single part of the system, or on the entire plant, using the simplest and most intuitive language: Reality, preferably “Augmented”. The compact plant exemplifies a typical workshop consisting of operating machinery, collaborative robots, measurement and control systems.

It is completed by an in-line assembly system and “additive” technology, which is increasingly characterising modern production systems, and which in this application are used for the production of pieces for “urgent” control. The aim was to design a plant solution which despite adopting automation, also considers people as an essential and quintessentially irreplaceable element due to their sheer flexibility, a fundamental pillar of every single workshop of the future.

Operators are supported in workshop supervision with all the most modern, practical, intuitive and “intelligent” equipment available to date. Simply by interfacing with objects of everyday use, such as a smartphone or tablet, the plant “dialogues” with us: parts of and the entire system are “smart connected” to the net and based on the real image viewed on the device’s videocamera, the app collects information provided by various plant parts, including geometric information, technical documentation and real time operating information.

The plant’s flexibility, versatility and “intelligence” are palpable not only in its overall vision, but also in every single part. The measurement and control island provides an infinite amount of information, based on its very own “intelligent” system”: from simple size measurements to the statistical elaboration thereof, indicating trends in measured characteristics and the process as a whole. It also ensures compliance with geometric tolerance settings and comparison with theoretical values. The measurement system provides discrete points which are suitably elaborated to provide more or less complex geometric entities, ranging from simple two-dimensional profiles to complex surfaces and mathematical models. This enables the mathematical reconstruction of real objects, to compare theoretical models with measured ones and to correct any object or process anomalies. Lastly, it also provides information on operational status, environmental conditions and machinery parameters usable for preventive and predictive maintenance.

Smart Factory Partners: